In today’s rapidly evolving electronics landscape, custom PCBs have become more than a technical requirement—they are strategic tools that enable innovation. Off-the-shelf boards often fail to meet the unique electrical, mechanical, or thermal demands of advanced devices. From custom flex PCBs used in wearable and foldable electronics to custom PCB board designs tailored for medical imaging systems, industrial controllers, and mobile devices, tailored circuit boards offer performance, reliability, and miniaturization that standard PCBs cannot achieve.

As devices shrink, operate at higher speeds, and become more connected, manufacturers increasingly rely on custom PCB fabrication and custom PCB assembly services to maintain a competitive advantage. This article explores the value of custom PCB solutions, the design and production process, real-world applications, and why partnering with an experienced manufacturer is essential for both prototyping and large-scale production.

A custom PCB is a printed circuit board engineered specifically to satisfy the unique requirements of a product. Unlike generic boards, custom PCBs are optimized for signal integrity, form factor, thermal performance, and functionality.

Key attributes of custom PCB boards include:

Tailored Layouts – Routing is optimized for high-speed signals, power delivery, or RF circuits to ensure reliable operation in complex electronic systems.

Form Factor Flexibility – Custom flex PCBs or rigid-flex combinations allow boards to fit into irregular enclosures, wearable devices, or compact industrial equipment.

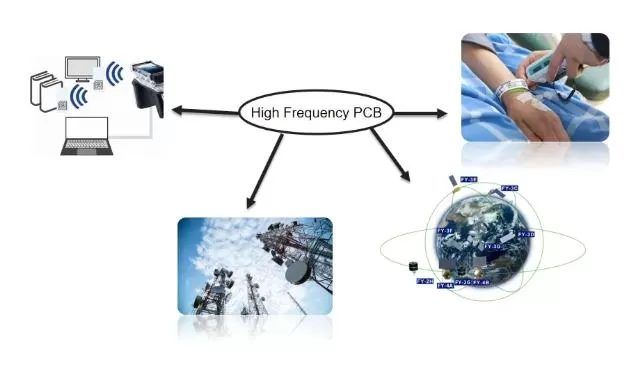

Specialized Materials – High-frequency laminates for 5G ( 5G PCB ) or RF applications, and metal-core substrates for heat dissipation in high-power electronics.

Unique Features – Embedded passives, controlled impedance, multi-layer stackups( multi-layered boards), and selective via placements tailored to device requirements.

By using custom PCB design services, engineers can align board performance precisely with product specifications, minimizing design compromises and enhancing reliability across industries.

Creating a high-quality custom PCB involves multiple critical steps:

1. Concept & Requirements

Engineers start by defining the technical requirements: voltage ranges, current loads, signal speed, size constraints, mechanical limits, and environmental factors. A mobile device PCB emphasizes compact HDI layouts and low-power operation, while a medical device PCB requires traceability, high reliability, and compliance with regulatory standards such as ISO 13485 or UL.

2. Custom PCB Board Design

Using advanced CAD tools, designers generate schematics and layouts balancing electrical performance, thermal management, and manufacturability. During this phase, simulation verifies signal integrity, thermal behavior, and mechanical stability. Custom PCB builders focus on reducing EMI, optimizing ground and power planes, and minimizing trace lengths for high-speed circuits.

3. Material Selection

Materials are chosen based on the device application. Standard FR-4 is common for consumer electronics, while flexible polyimide sheets support wearables and foldable gadgets. High-frequency laminates or ceramic substrates may be used for RF, medical, or aerospace electronics. For high-power applications, metal-core PCBs or thick copper PCBs are selected for efficient heat dissipation.

4. Custom PCB Fabrication

Fabrication involves precision imaging, copper etching, microvia drilling, lamination, plating, and surface finish application. Multilayer, flex, and rigid-flex boards require meticulous attention to ensure mechanical stability and high reliability. Manufacturers often incorporate AOI and X-ray testing during fabrication to detect defects early.

5. Custom PCB Printing and Assembly

Beyond fabrication, many custom PCB makers provide silkscreen printing, solder mask application, surface finishes (ENIG, HASL, OSP), and full SMT/THT assembly. Automated assembly ensures high-precision placement, even for dense mobile PCBs or medical devices requiring strict quality standards.

6. Testing & Validation

Comprehensive testing validates performance under real-world conditions. Thermal cycling, vibration testing, high-frequency signal verification, and functional checks are standard. These steps are especially critical for medical electronics, aerospace systems, and industrial controls.

Custom Flex PCBs – Designed for wearables, foldable displays, or compact IoT sensors where boards need to bend.

Custom Rigid-Flex PCBs – Combine rigidity and flexibility, suitable for aerospace electronics, medical implants, or advanced consumer electronics.

Custom Multilayer PCBs – High-density boards for smartphones, tablets, servers, and IoT devices.

Custom Prototype PCBs – Fast-turn prototypes allow rapid testing and iterative development before scaling to full production.

Medical devices demand precision, reliability, and compliance. Custom PCB boards power diagnostic imaging systems, implantable devices, and patient monitoring equipment. Manufacturers rely on custom PCB fabrication and assembly services to ensure biocompatibility, regulatory compliance, and consistent performance.

From smartphones to wearables and audio devices, custom PCB design enables miniaturization without compromising performance. Custom flex PCBs allow wireless earbuds, foldable phones, and wearable sensors to fit into sleek enclosures. Rapid-turn custom PCB prototyping accelerates time-to-market for innovative products. Here click for telecom circuit boards.

Advanced driver-assistance systems (ADAS), flight control boards, and cockpit electronics require robust custom PCBs. Rigid-flex designs, high-power substrates, and thermal management are essential to ensure durability under vibration, extreme temperatures, and high-frequency signals.

Factories and IoT networks use custom PCB prototypes and scalable production for sensors, wireless modules, robotics, and controllers. Optimized designs integrate multiple functions into a single board, reducing footprint and simplifying assembly.

Innovation – Tailored designs provide differentiation in competitive markets.

Fast Turnaround – Rapid prototyping accelerates development cycles.

Cost Optimization – Optimized layouts and component placement reduce production costs.

Scalability – Custom prototypes can quickly scale into mass production.

Reliability – Carefully engineered boards achieve higher durability and meet safety standards, crucial in medical, mobile, and aerospace applications.

Embedded Components – More devices will integrate resistors, capacitors, and sensors directly into PCB layers.

Advanced Materials – Ceramic substrates and low-loss laminates for high-frequency or high-power applications.

Flexible Electronics – Growth in wearable tech, foldable devices, and compact sensors will increase demand for custom flex PCBs.

Sustainable Solutions – Eco-friendly materials and energy-efficient custom PCB production processes are gaining prominence.

AI-Driven PCB Design – Software tools increasingly optimize layouts for signal integrity, thermal performance, and cost efficiency.

WEIYUANDA PCB provides end-to-end custom PCB solutions, supporting innovation from prototype to large-scale production:

Comprehensive Product Line – Single-layer, multilayer, rigid-flex, and flex PCBs for medical, industrial, mobile, and consumer applications.

Full Custom Services – Design, fabrication, printing, and assembly, including fast-turn prototypes.

Advanced Facilities – Precision imaging, automated SMT assembly, and rigorous testing labs.

Global Reach – Serving clients in over 40 countries across industries.

Quality Assurance – International certifications and strict QC procedures ensure reliable performance.

Whether you need a prototype, high-volume production, or custom PCB printing and assembly, WEIYUANDA PCB delivers complete, dependable solutions.

In today’s competitive electronics market, customization is no longer optional. Custom PCBs enable medical devices, wearable technology, mobile gadgets, and industrial systems to achieve superior performance, compact form factors, and reliability. Custom flex PCBs make wearables and foldable devices possible, while fast-turn prototypes accelerate innovation cycles.

By combining engineering expertise, precise fabrication, and assembly capabilities, WEIYUANDA PCB helps companies transform concepts into high-performance products. With decades of experience, global supply capabilities, and a focus on fast, custom, and reliable PCB services, WEIYUANDA PCB is more than a PCB supplier—it is a long-term partner driving innovation across industries.